O mundo das máquinas de panificação que são mais flexíveis e dinâmicas

subestimados no mundo agitado da panificação comercial, Máquinas de panificação garantir que produtos de panificação de alta qualidade sejam produzidos rapidamente, de forma confiável e eficiente. Essas máquinas transformaram a arte e ciência da panificação desde seus humildes começos até o que é hoje.

tipos de máquinas de panificação

1.Mixidores de massa

Qualquer padaria de sucesso deve começar com massa. os misturadores de massa vêm em muitos tamanhos e configurações para diferentes tipos de padarias, pequenas máquinas portáteis para uso doméstico por padeiros ou grandes misturadores espirais industriais para fins comerciais. desta forma, eles simplificam o procedimento de combinação de farinha de trigo,

2. divisores-redondadores

Quando misturados, a massa precisa ser dividida em pedaços semelhantes antes de ser formada para provar. divisores-redondadores fazem este trabalho automaticamente dividindo a massa consistentemente em pesos específicos enquanto os redondeiam para se preparar para as etapas subsequentes. isso economiza tempo, mas também mantém a padronização do tamanho

3.Lanças e rolos

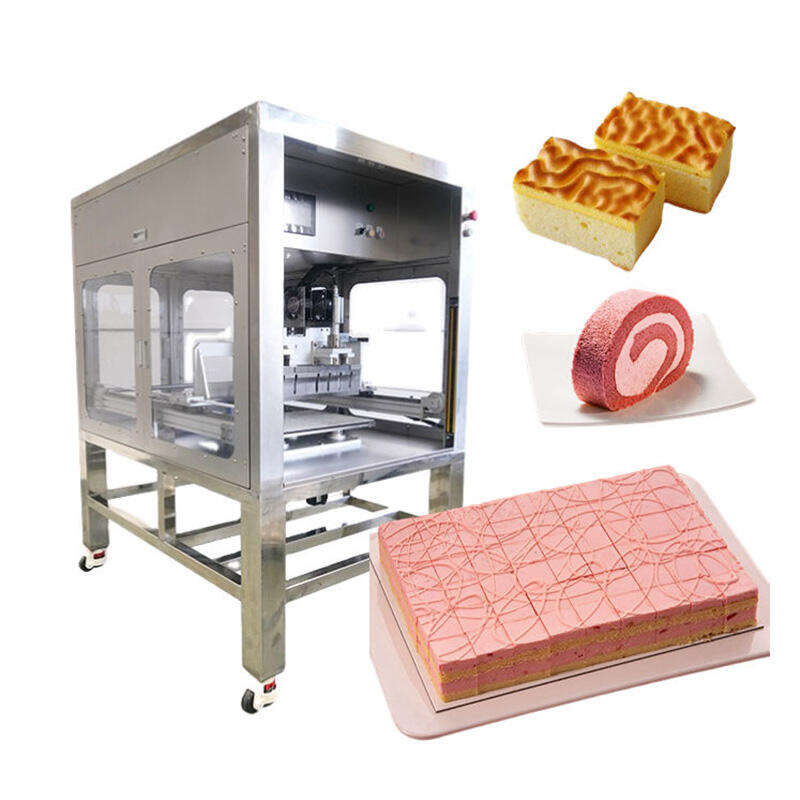

produtos como massas, bolos ou pães planos nunca podem se mover sem chapas e rolos. eles garantem espessuras precisas durante o enrolamento para melhorar a cozedura uniforme, bem como a textura adequada. outros têm uma característica ajustada que permite aos que preparam padrões ou formas que são particularmente deliciosas quando assadas.

4. moldeiros e moldadores

A maioria das máquinas de moldagem contém variedades de desenhos adequados a vários artigos de panificação que também podem ser programados.

5.profissionais

O processo de fermentação responsável pelo sabor, textura e qualidade global é otimizado por estes dispositivos através da manutenção de certas temperaturas e umidade.

6. fornos

O equipamento mais importante dos padeiros são os fornos. Eles agem tantos tipos de produtos quanto há tipos de fornos disponíveis, como fornos de convés, transportadores ou rotativos. Outras capacidades avançadas incluem o gerenciamento de temperatura, controle de umidade e até programação de perfis de panificação para consistência na padaria

7. refrigeradores

Os produtos devem ser arrefecidos antes de poderem ser embalados ou exibidos após serem cozidos. Os refrigeradores ajudam a diminuir a temperatura lentamente e a evitar a perda de água para que os produtos permaneçam sempre frescos.

impacto na indústria do panificação

A inovação na indústria das máquinas de panificação acompanhou a evolução das exigências de panificação. Os avanços tecnológicos levaram a melhorias destas máquinas, resultando num aumento da eficiência, produtividade e criatividade dos padeiros.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

TH

TH

FA

FA

MS

MS

AZ

AZ

KA

KA

BN

BN

LA

LA

MN

MN